PRODUCT

PHOTONIC DEVICE ALIGNMENT & ASSEMBLY

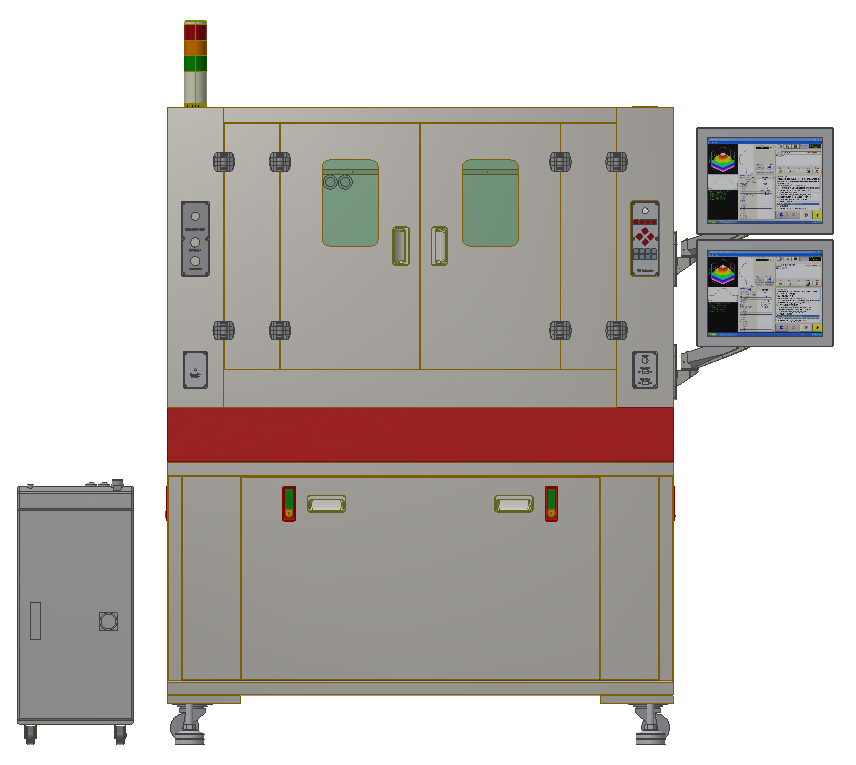

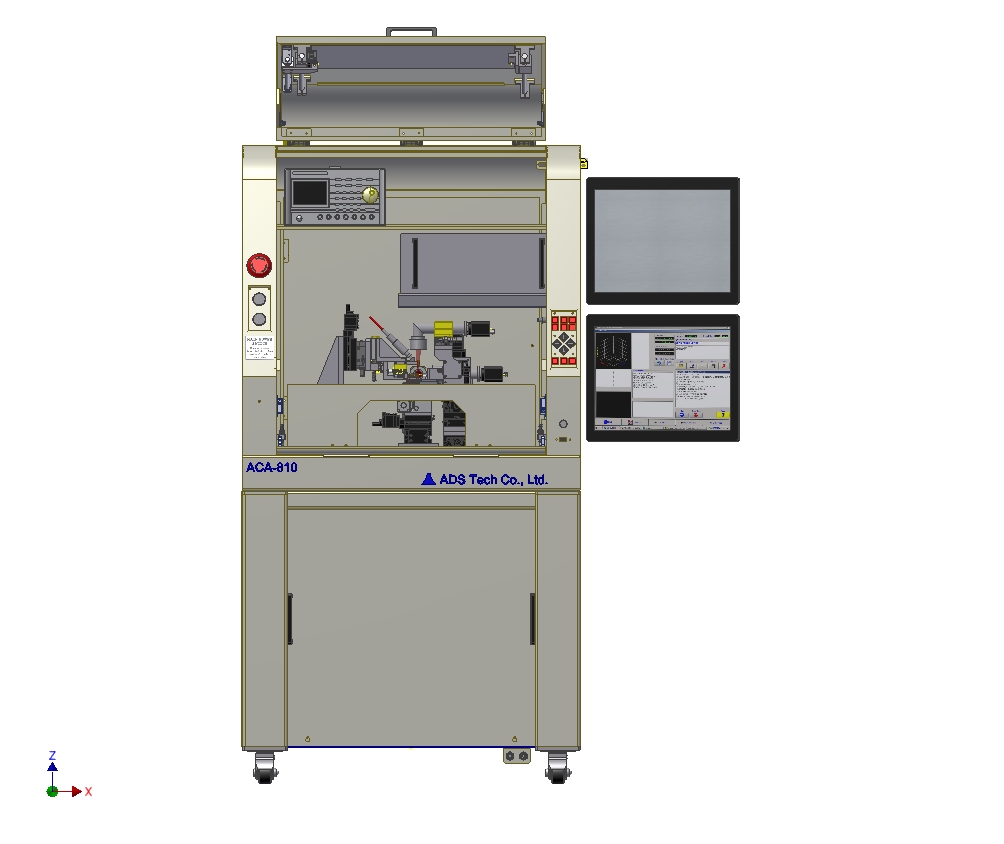

A Modular Approach to Machines

Over 600 machines delivered globally, from standard off-the-shelf to highly-customized, highly-automated solutions

Since 1999, and now with in excess of 652 systems in the field, ADST is the market leader when it comes off-the-shelf and individually customized solutions for automated micro-assembly, packaging and testing of photonics-based components, micro-optic assemblies and opto-electronic devices.

Our machines employ established and industry-recognized assembly technologies-micro-positioning, active/passive precision alignment, attachment via welding, soldering and/or bonding, and optical inspection. ADST also provides a suite of test capabilities for individual components and assembled hybrid opto-electronic devices. Moreover, with everything being controlled by our flexible process control software, the product platforms described below become so much more than just the sum of their parts.

The technologies available to ADST and implemented in both the stand-alone and newer in-line machine solutions translate into a broad and established spectrum of production process capability. We are continually refining capability, modularity and design so that these systems reliably and cost-effectively meet strict efficiency and yield requirements even for cutting-edge production processes.

For the team here at ADST, these tasks are already simply everyday challenges

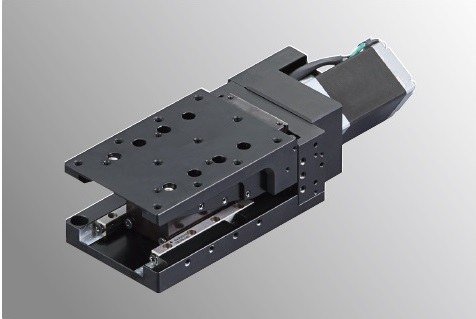

VERTICAL ALIGNMENT SYSTEM

* High Precision and Accuracy

* Long Team Realibility

* High Speed Alignment

LENS ALIGNMENT SYSTEM

* Ball Lens Alignment

* Drum Lens Alignment

* Lens Holder Alignment

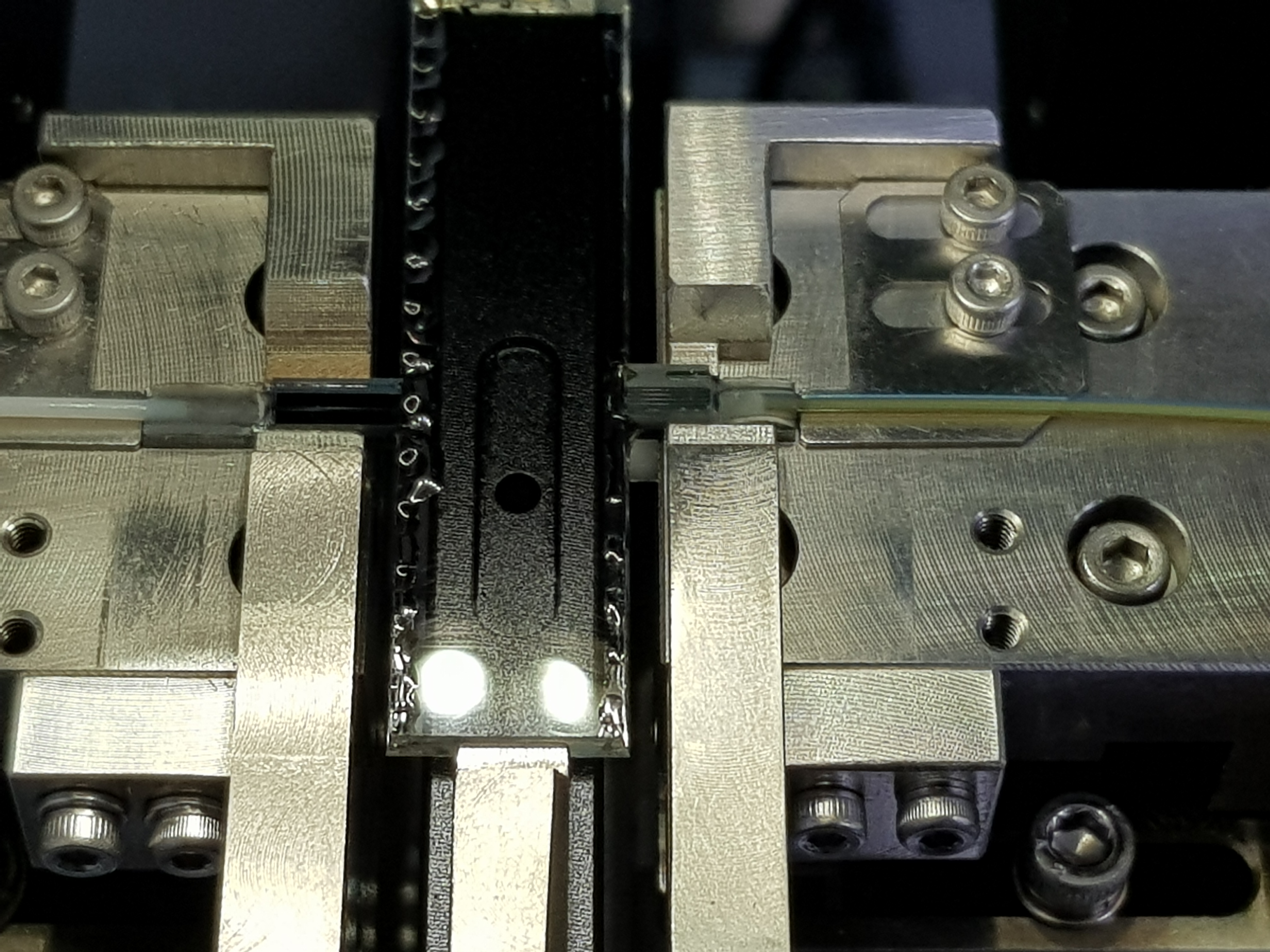

FIBER ARRAY ALIGNMENT SYSTEM

* AWD with Receptacle Alignment

* Single Fiber Alignment

AUTOMATIC CWDM CHIP TEST SYSEM

* FULLY AUTOMATIC MEASUREMENT

* CWDM ANALYSIS TOOL

* HIGH PRODUCTIVITY

PHOTONIC DEVICE TESTING

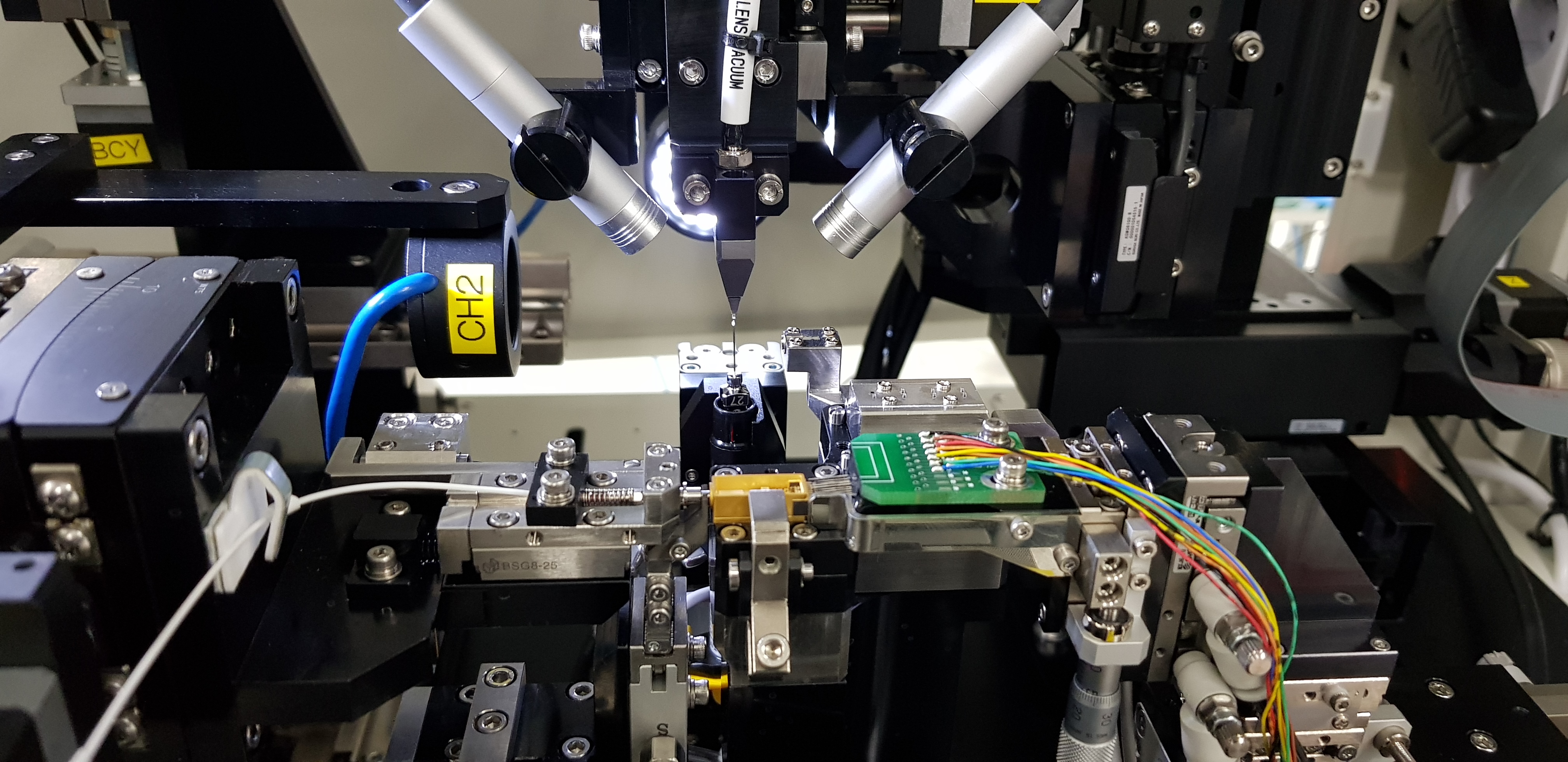

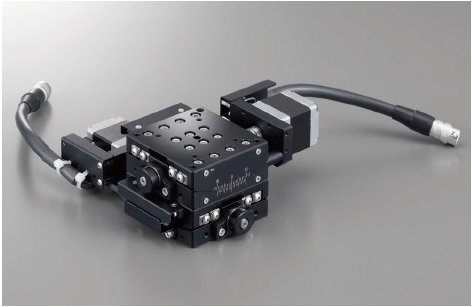

COC ALIGNMENT SYSTEM

* DC Probing and RF Probing.

* High Speed Alignment.

* High repeatability and reporductibility.